KJ Martin was about to take the court for the second round of the 2023 NBA Slam Dunk Contest when he made a unique substitution.

With help from his father, Kenyon Sr., a 15-year NBA veteran and former All-Star, the younger Martin switched out a traditional basketball for one that was being held in a glass case.

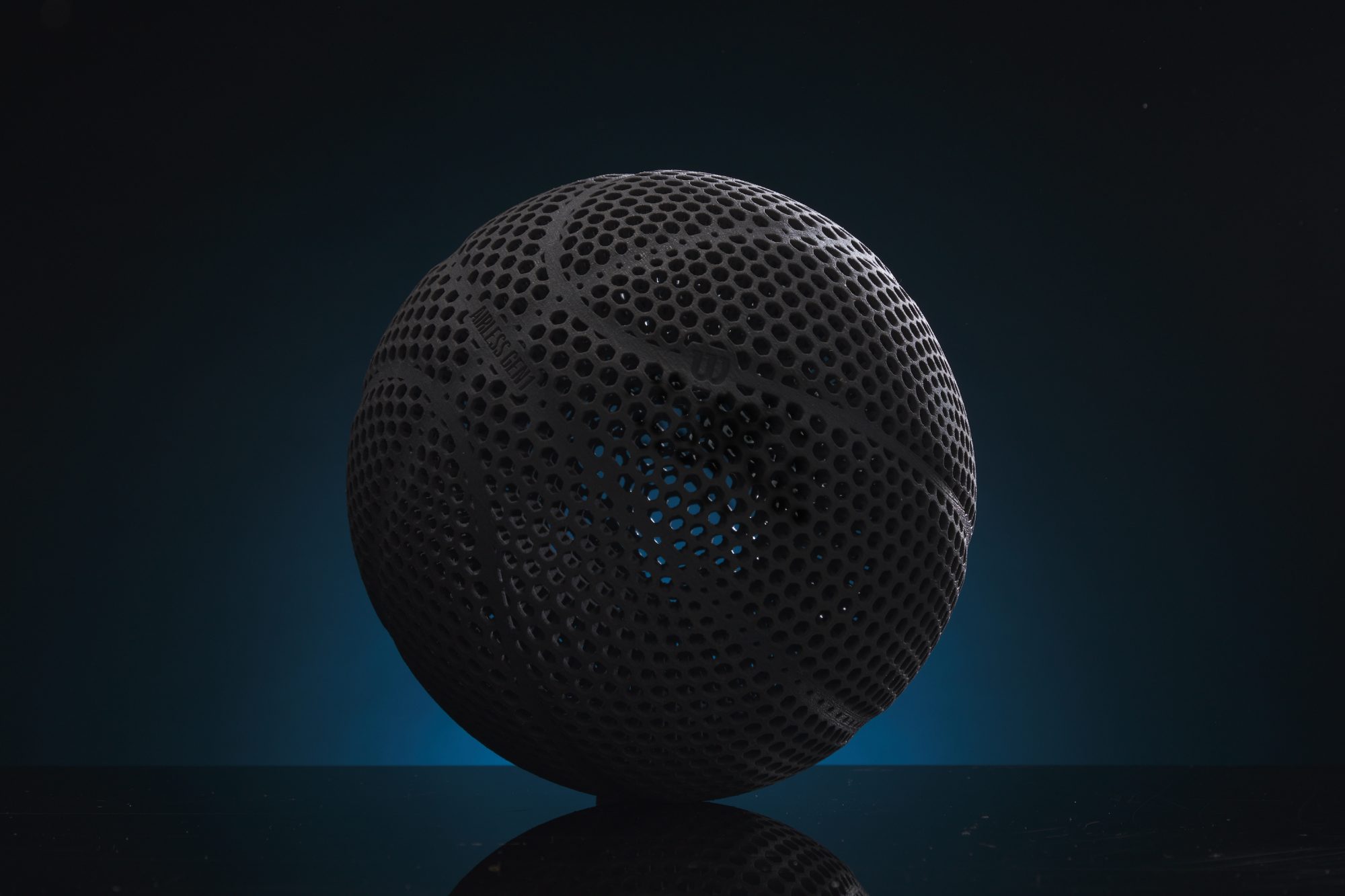

The special ball, made by Wilson, the league’s official game ball manufacturer, bounced like a regular ball, except it wasn’t. It was black, hollow, and manufactured with a 3D printer instead of the regular process, which involves drying leather. For his dunk, Martin, then a Rocket, caught a lob from his father, and cocked it from his legs to behind his head for a reverse jam.

The modern basketball has evolved slightly over the game’s 130-plus-year history, but significant innovations have been more of a joke than a serious pursuit. Tim Duncan and Steve Nash once starred in a Bridgestone tire commercial in which the company manufactures a ball from its trademark rubber that hardly makes a sound.

But unlike Bridgestone, Wilson actually went through with it and is betting on itself as much as technological innovations by going into the airless ball space. On Friday, an updated version of the ball, called the Airless Gen1 will be available for purchase on Wilson’s website for $2,500. Only a few hundred have been made, and it raises some questions about changes to a product that virtually no one has ever asked. What’s the market for an airless basketball? And what is its potential? Is it a niche product? Or something that can one day replace the innumerably dotted orange globe in a college or NBA game?

“Target audience is the big question and has been the big question for a while now as we’ve been developing this,” David Picioski, director of global brand partnerships and collaboration at Wilson tells Front Office Sports.

Wilson says it wasn’t necessarily looking to reinvent the basketball. The company is always investigating product innovation, whether that’s a price point or a manufacturing process, and started to do so with the basketball to attack one of customers’ most common complaints: Balls eventually go flat. The grievance isn’t unique to the sport as footballs and soccer balls can lose air. Just ask the Patriots.

The company began developing prototypes through additive manufacturing, a type of 3D printing that makes precise geometric shapes by printing in 2D layers before going through rigorous testing. When Wilson was ready to give its new invention some real run, it called Martin to see whether he wanted to use it in last year’s dunk contest. He agreed.

Martin had a less-than-memorable reaction when he first saw it.

“I was kind of confused,” Martin tells FOS.

The ball had the same size, bounce, and weight as a regulation ball, but it was hollow with holes throughout and a different texture (a customized elastic polymer, according to Wilson). It has no air pressure, which can impact the shooting and dribbling of a ball, so it will perform the same in every arena or climate. The 3D printing allows for the ball to be made more sustainably than the traditional method. Each Airless Gen1 is identical, with a single layer and no leftover materials, whereas the traditional process requires cutting eight pieces of leather for a four-layer ball.

After Martin’s dunk, interest in the ball skyrocketed. The 6’6″ forward said everyone wanted to try the ball, including dunk contest judges Shaquille O’Neal and Dominique Wilkins. He tried to get as many hands on the ball as he could. Meanwhile Wilson began soliciting the opinions of people throughout the NBA.

“The response was just so overwhelmingly positive and ‘How do I get one?’” says Kevin Krysiak, senior director of global research and development, team sports at Wilson. “We kind of fast-tracked it.”

Martin had the chance to be one of Wilson’s testers for the product, but would he actually spend $2,500 on one?

“Yeah, I would,” Martin says. “Just based off the experience I had in the dunk contest and it would kind of be like a memorabilia moment.”

Martin, now a member of the 76ers, seems to fit Wilson’s target audience. Picioski said the company isn’t looking for customers to buy one and take it for a run at Rucker Park. They’re going for sports fans, collectors, and tech enthusiasts who enjoy owning a piece of innovation before everyone else. Think of those who have already paid over $3,000 for Apple’s new Vision Pro despite its lack of necessity.

“In a way we feel like we’re creating a new audience by merging these groups together and forming something that really hasn’t existed before for a product,” Picioski says.

Wilson’s plans for the product get more uncertain once they sell out of the Airless Gen1. They coined it with the idea of subsequent installments, but the quantity and price remain in flux. Krysiak says the high price point is partly due to scarcity and partly because of manufacturing limitations—but the ball’s ceiling is directly tied to both. If it can be sold for a price that rivals the traditional basketball (NBA game balls sell for roughly $200; recreational ones range from $25 to $50), maybe it can become more than a niche product, and perhaps make its way into a pickup game. Krysiak says the company is betting that, in the future, additive manufacturing becomes more mainstream, and therefore cheaper, to mass produce.

“I would say theoretically anything is possible,” Krysiak says. “It’s definitely going to take a while for this idea to get there.”

Currently, the Airless Gen1 isn’t fully recyclable. Wilson would like it to be. Could a material supplier approach Wilson with a medium that is more sustainable? The company wouldn’t mind. For context, Wilson produces millions of regular basketballs each year for NBA game balls and retail. The roughly 200 Airless Gen1s for sale are close to the maximum they can currently make at that quality.

“We’re very early in this,” Krysiak says. “It happened really fast and we could see it coming, but we didn’t see it this fast. The response from last year was like, ‘I want it, I want it, I want it,’ and we can do it, but this is what it’s going to be. We’re being straightforward that it’s going to be costly because there’s a tremendous amount of engineering and a tremendous amount of warp that went in to get us here.”

When asked for his preference, Martin says he still prefers the traditional basketball simply because of the feel. The airless ball doesn’t have the dotted leather texture he’s used to, which was his biggest adjustment and his primary piece of feedback for Wilson. Martin speculated if there is a world in which the leather texture can be printed on, the ball can really catch on. But if an entire generation were to grow up playing with the airless ball and its current texture, then it might not matter. That’s why Martin, who just turned 23 and is in his fourth year as a pro, wouldn’t be surprised if the ball is mainstream toward the back end of his career.

“Nowadays, technology is crazy and it’s improving year by year,” Martin says. “No telling how that basketball will be used.”

Unfortunately for Martin, he, like everyone else, will have to take his shot at buying an airless ball online. After his cameo in the dunk contest, he had to return it.

![[Subscription Customers Only] Jun 15, 2025; Seattle, Washington, USA; Botafogo owner John Textor inside the stadium before the match during a group stage match of the 2025 FIFA Club World Cup at Lumen Field.](https://frontofficesports.com/wp-content/uploads/2026/02/USATSI_26465842_168416386_lowres-scaled.jpg?quality=100&w=1024)

![[Subscription Customers Only] Jul 13, 2025; East Rutherford, New Jersey, USA; Chelsea FC midfielder Cole Palmer (10) celebrates winning the final of the 2025 FIFA Club World Cup at MetLife Stadium](https://frontofficesports.com/wp-content/uploads/2026/02/USATSI_26636703-scaled-e1770932227605.jpg?quality=100&w=1024)